|

Final Blueprint

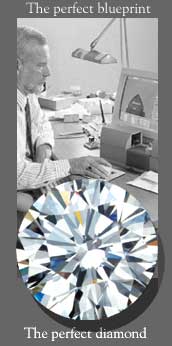

After sawing, each diamond is returned to the Marker for final blueprint specifications. Creating the perfect 3D diamond blueprint is a process unique to RAND. First the Marker will place the sawn diamond on his 3-D imaging system and superimpose the specifications of the perfect RAND Diamond onto the rough diamond image. Utilizing proprietary software the Marker will then develop an exact blueprint for that diamond, ensuring that each facet angle will be symmetrical in both two and three dimensions. RAND is the only diamond to offer three-dimensional symmetry, which results in its superior brilliance.

After sawing, each diamond is returned to the Marker for final blueprint specifications. Creating the perfect 3D diamond blueprint is a process unique to RAND. First the Marker will place the sawn diamond on his 3-D imaging system and superimpose the specifications of the perfect RAND Diamond onto the rough diamond image. Utilizing proprietary software the Marker will then develop an exact blueprint for that diamond, ensuring that each facet angle will be symmetrical in both two and three dimensions. RAND is the only diamond to offer three-dimensional symmetry, which results in its superior brilliance.

Before cutting begins, each diamond's blueprint will be downloaded onto sophisticated measuring equipment in the factory. This equipment is an crucial part of our strict Quality Control procedures and ensures that the diamond is polished to its exact blueprinted specifications.

This unique blueprint will also appear on each RAND Provenance Report.

|

|